Throughout the coronavirus pandemic, countries all over the world are not only facing the threats of a novel virus but also the volatility of the supply chain.

Since 2020, suppliers and manufacturers are encountering stock shortages, delays in fulfillment, and delays in the shipment of orders. According to experts, these challenges are persisting through 2022. Rocks and crystals trading is not exempt from these supply chain issues.

For the purpose of education and transparency, we cite the top issues many rock shops are facing at present. And if you're a rock shop owner reading this, we also included some tips to tackle these issues head on.

1. Scarcity of Supply

When the pandemic broke, you'd think people would slow down on buying gems, crystals, and minerals. But the opposite of that is true for the gem trade. Despite the price increases, consumers never stopped buying crystals and the demand for crystals for a wide range of uses is steadily growing.

Some stones get an overwhelming demand than the rest due to their rarity and properties that suppliers couldn't keep up with, like moldavite, sodalite, and blue lace agate. Insufficient supply is mostly felt by mines that extract specific crystals on a seasonal basis. This is also driven by factors such as if lapidaries stopped cutting or trading certain stones, or if factories stopped producing them.

We prevent this from affecting our own input by ordering products (especially those in limited supply) from mines and manufacturers as soon as possible. We also order in big quantities.

2. Rising Shipping Cost

The Covid-19 pandemic has resulted in the slow circulation and shortage of available shipping containers worldwide, driving up freight costs. What used to be a one-way shipping fee of $3,000 from Brazil (one of our main major gem sources) pre-pandemic has now increased to a whopping $12,000 ” for the same route!

What this means for customers is that A.) It will jack up the prices for all products in the coming months and B.) The shipment of orders will take longer than usual.

Although temporary, the container shortage problem isn't ending anytime soon. Industry experts say it will likely resolve at the end of this year, or early next year when the trade situation eases.

Regardless, we at Stonebridge Imports will do our best to process your orders promptly to avoid unnecessary delays.

3. Shifting Consumer Attitudes

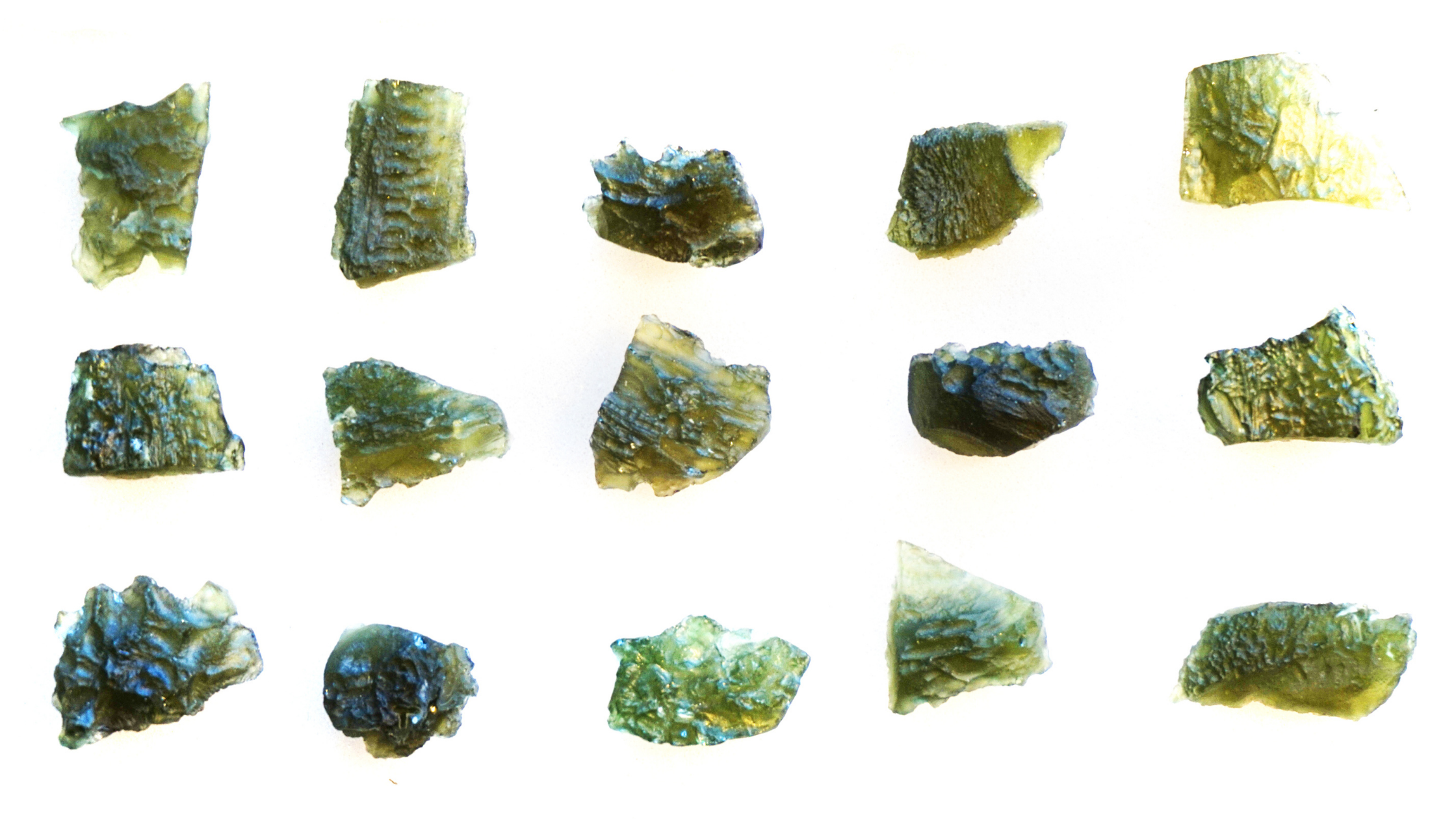

Like all other trends, customer behaviours and attitudes are always changing. This happened more rapidly when the global pandemic struck. Customers now want faster delivery of their orders and a lightning-speed response to their queries.

With a dwindling attention span coupled with the need to get what they need in an instant, customers now demand a smoother and hiccup-free shopping, online and in-store. Anything short of these is tantamount to poor customer experience. Consumers are constantly shaping and reshaping what stellar customer service should look like based on their evolving needs.

To manage, rock shops must have an agile supply chain and to automate their purchase systems. When these 2 are in place, stores can fulfill spikes in demand with ease. It's also best to explore multiple channels for taking orders and to invest in an advanced inventory management software.

Ideas to Address Supply Chain Concerns

The pandemic has really shaken up supply chains across industries, an event that's challenging businesses to be more adaptable and competitive so as to remain relevant. Fortunately, there are several steps you can take to meet your customers' needs without draining your supplies.

Every rock shop or supplier's situation will be different from others, but one or a combination of these techniques may help rock shop owners weather supply chain issues.

1. Broaden Your Supplier Choices

Diversifying your sources (e.g., building a network of suppliers outside the country) gives you more product choices and various options for delivery. Also, adding more suppliers to your supply chain allows you to be more flexible and to adjust accordingly to specific changes in the market.

For many stores, having diverse sources is an effective supply chain strategy which usually results in sustained profits and customer satisfaction and growth.

2. Seek Alternative Shipping Ports

Due to overwhelming supply chain demands in various industries, ports can experience congestion and capacity issues. Identify alternative ports to prevent delays in fulfilling your orders. This will help you stay right on schedule and meet customer demands even when unforeseen events take place or when there's a sudden increase in orders.

For bulk orders, consider having your supplies shipped via air and sea. A boat can carry a 20-ft container that can fit up to 20 tons (almost 19,000 kg) and is ideal for massive specimens. Air freight is best for highly popular items as well as lighter products like jewellery and accessories, although this option could be a lot more expensive (per weight increments) than sea shipment.

Since we serve mostly small rock shops, we at Stonebridge absorb the shipping cost to continuously give our wholesale customers a profitable supply.

3. Boost Your Process of Forecasting Demand

The best way to boost forecasting is to automate your process of calculating these metrics. This is especially important for online store owners who are constantly keeping track of their inventory levels, warehousing costs, and customer demands, ensuring all these figures are balanced to avoid inventory shortages or stockouts.

An automated inventory provides you with forecasting tools and informs you about how much cash you have on hand so you can make decisions right away. Doing this can also streamline your inventory counts.

Sources:

6 Supply Chain Challenges & Tips To Overcome Supply Chain Issues in 2021. (2021, June 8). Skubana. Accessed at https://www.skubana.com/blog/future-of-supply-chain

Baum, N. (n.d.). CONSUMER BEHAVIOR IS SHIFTING: FIVE REASONS WHY YOU NEED TO ACT NOW. C + R Research. Accessed at https://www.crresearch.com/blog/consumer-behavior-shifting-five-reasons-why-you-need-act-now

Friesen, G. (2021, September 3). No End In Sight For The COVID-Led Global Supply Chain Disruption. Forbes. Accessed at https://www.forbes.com/sites/garthfriesen/2021/09/03/no-end-in-sight-for-the-covid-led-global-supply-chain-disruption/?sh=69120d53491f

Henderson, C. (2020, August 4). Automated Inventory Control - How It Works & How It Can help. Any Connector. Accessed at https://anyconnector.com/en/business-process-automation/automated-inventory-control.html